RDT PA-03

SCBA washing machine for cleaning up to 3 SCBAs or 8 helmets

Disinfecting and drying require add-on modules.

Modular design for customizability

Thanks to its modular design, RDT PA-03 can easily be configured to meet your specific needs and requirements in terms of cleaning, disinfecting and drying.

RDT PA‑03 main unit

Featuring a fully automated system for water supply, cleaning (including the addition of the detergent), rinsing and wastewater discharge, the RDT PA-03 main unit allows you to clean up to 3 SCBAs simultaneously.

The SCBAs can be put into the machine complete with a 6-litre or a 6.8-litre cylinder or two 4-litre cylinders attached to them. If the SCBAs are equipped with two 6.8-litre composite cylinders, only two units can be processed simultaneously.

Nozzles and rotating drum for perfect cleaning

RDT PA‑03 is a top-loading washing machine. The SCBAs or helmets to be cleaned are fastened to the machine's drum, which rotates throughout the operation of RDT PA‑03.

In three corners of the housing, there are pipes with stainless-steel spraying nozzles (21 in total). In combination with the rotating drum, these nozzles guarantee that the equipment in the machine gets sprayed on all sides for perfect cleaning.

Liquid-saving closed-loop system

The liquid required for spraying is drawn from the sump, which is located in the base of the machine, by means of a pressure pump and fed to the stainless-steel nozzles at a pressure of approximately 3 bar. The nozzles spray the SCBAs or helmets with the pressurized liquid in a targeted manner. The liquid running off the equipment is collected in the sump. From there, it is fed back to the nozzles via the pump.

Wastewater

After each cycle, the wastewater is pumped off fully automatically and discharged into the sewage system via the wastewater hose.

Specifications of the RDT PA‑03 main unit

| water section: | stainless steel |

| base and lid: | texture-painted aluminium |

| dimensions (w × d × h): | 800 × 800 × 1100 mm |

| weight: | approx. 135 kg |

| water connection: | ball valve, ≥ ¾″ |

| water supply pressure: | 2.5 – 6 bar |

| water-heating unit: | approx. 35 °C |

| power supply: | 230 V, 50 Hz |

| power consumption: | 2.9 kW |

- excl. contol panel

- drum drive, pump and water-heating unit

SCBA pressurization

SCBAs that are put into the machine without their cylinders need to be pressurized using miniature compressed-air cylinders.

Miniature compressed-air cylinder

Module 1 – Fully automatic disinfectant supply unit

This module allows you to disinfect the equipment in the machine fully automatically once cleaning is complete.

Disinfecting SCBAs is not a must, but it can help to largely rid them of unpleasant odours that remain after cleaning, such as burnt smell. The lung-governed demand valves of SCBAs can also be disinfected, as can the insides of helmets (unless otherwise stated in the applicable care instructions).

Module 2 – Warm-air blower for RDT PA‑03

RDT PA‑03 can (at any time) be upgraded with a purpose-built warm-air blower featuring a thermostat-controlled heating unit.

The external blower, which can be installed to the right or to the left of the machine as well as above it, connects to the RDT PA‑03 main unit via a hose. It blows the warm air required for drying into the machine at a temperature of approximately 50 °C. The current temperature can be checked via an easy-to-read display on the blower housing. The main unit supplies the blower with power and controls its operation fully automatically, with the controller and the power port being included in the main unit.

RDT PA‑03 used in combination

with the warm-air blower

Specifications of the warm-air blower

| dimensions (w × d × h): | 210 × 190 × 450 mm |

| flexible connecting hose: | ⌀ 63 mm |

| length (shortenable): | 1.5 m |

| power consumption: | 1.2 kW |

- RDT PA‑03 main unit and warm-air blower used together

Module 3 – Helmet cleaning kit

The helmet cleaning kit allows you to quickly and easily install up to 8 helmets in the machine for processing.

Air dehumidification

During equipment drying with the warm-air blower for RDT PA‑03 (see module 2), moist air is released from the machine into the ambient environment. This results not only in a significant increase in air humidity, especially in settings with insufficient ventilation, but, among other things, also in considerably longer drying times.

Hence, it is strongly recommended that you use a dehumidifier to prevent an excessive increase in air humidity.

- Dehumidifier WDH 1200 HT

dehumidification capacity: up to 120 litres in 24 hours - Dehumidifier WDH 500 AH

dehumidification capacity: up to 50 litres in 24 hours

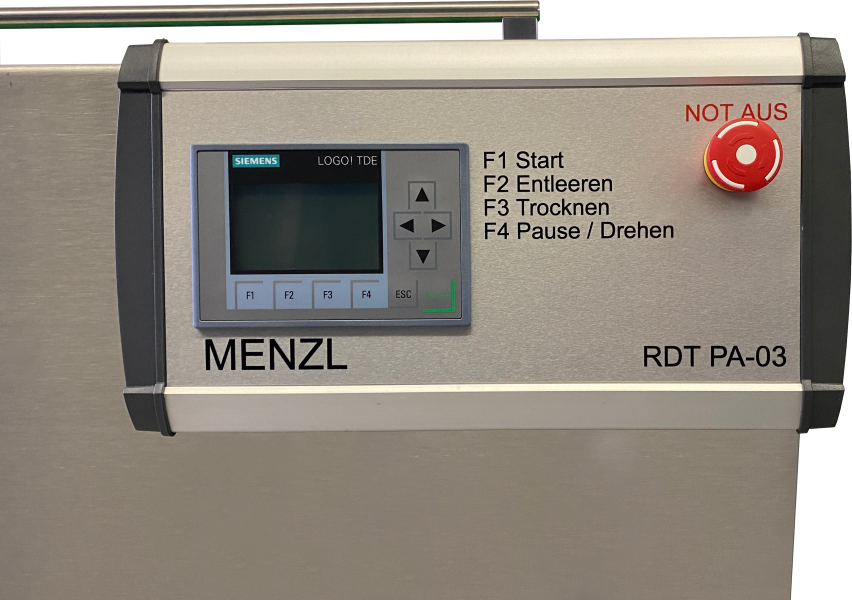

Adjustable detergent/disinfectant supply

Via the control panel, the amount(s) of detergent (and disinfectant) added as well as the timings for the individual functions can easily be adjusted to meet your specific needs and requirements.

Detergents and disinfectants suitable for RDT PA‑03

- Detergents: EW80 clean

- Disinfectants: EW80 des

Detergents and disinfectants that produce a lot of foam are not suitable for use with RDT PA‑03.

SCBAs and helmets can also be cleaned with special soap solutions. When cleaning a helmet, always follow the instructions provided by its manufacturer!

Manual dirty/clean indicator

The machine comes with a manual dirty/clean indicator that makes it easy to quickly indicate whether the equipment in the machine is dirty or clean. The indicator is magnetic, but it can also effortlessly be installed on non-magnetic surfaces by means of the included double-sided adhesive pads.

Article numbers

| RDT PA‑03 main unit | 330-891 |

|

Module 1 fully automatic disinfectant supply unit |

330-442 |

| Module 2 warm-air blower for RDT PA‑03 |

330-892 |

| Module 3 helmet cleaning kit |

330-366 |

| Miniature compressed-air cylinder 0.3 l / 200 bar, complete with valve |

160-007 |

| Dehumidifier WDH 1200 HT | 330-359 |

| Dehumidifier WDH 500 AH | 120-536 |

| Water softener | 330-746 |

.png)

.png)

.png)